Right so Friday night I travelled up to my Brother's in Birmingham in the 2 for her last drive as an n/a to fit all this lovely little lot:

Straight away we spent a while taking everything off, it's amazing how much bolts seize up in a year!

We then left it ready for Saturday.

First thing was to take the rear wheels to get the new Toyos fitted and balanced (why do we both have such impractical cars!) which cost me £7.50 each (up 50p due to new owner!).

We'd also realised that my brother had lent his Axel stands to his neighbour who was at work so we had reluctantly secured the car off the ground in 'not the ideal way' whilst I stood guard of wind or passing animals that may want to rub up against it! (there is wood on top of the bricks by the way)

We ended up starting about 1pm after a morning out and got to work.

First things on were the Turbo and the Apexi which didn't seem to fit in that snuggly.

Then all the coolant and induction pipes/hoses:

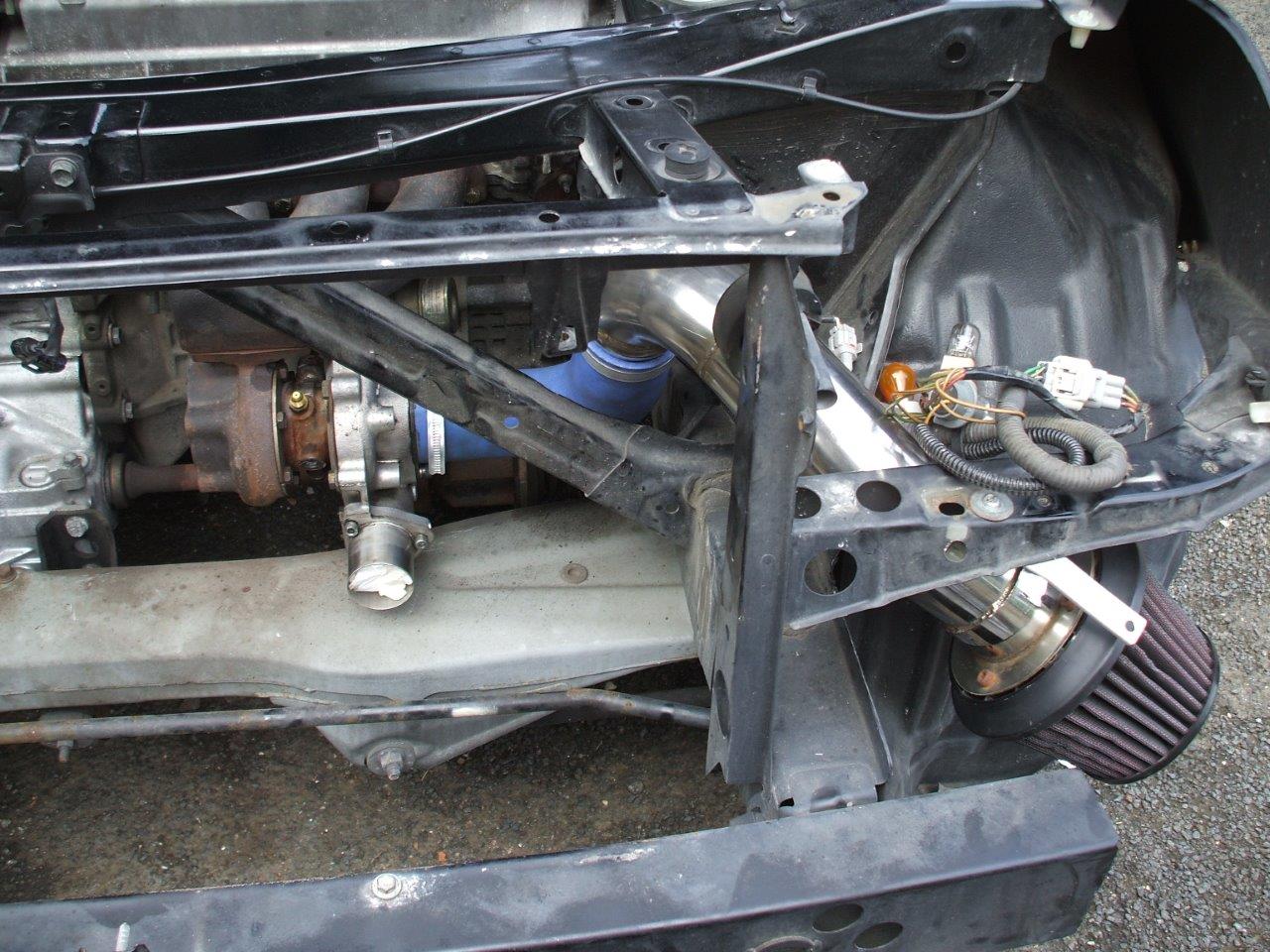

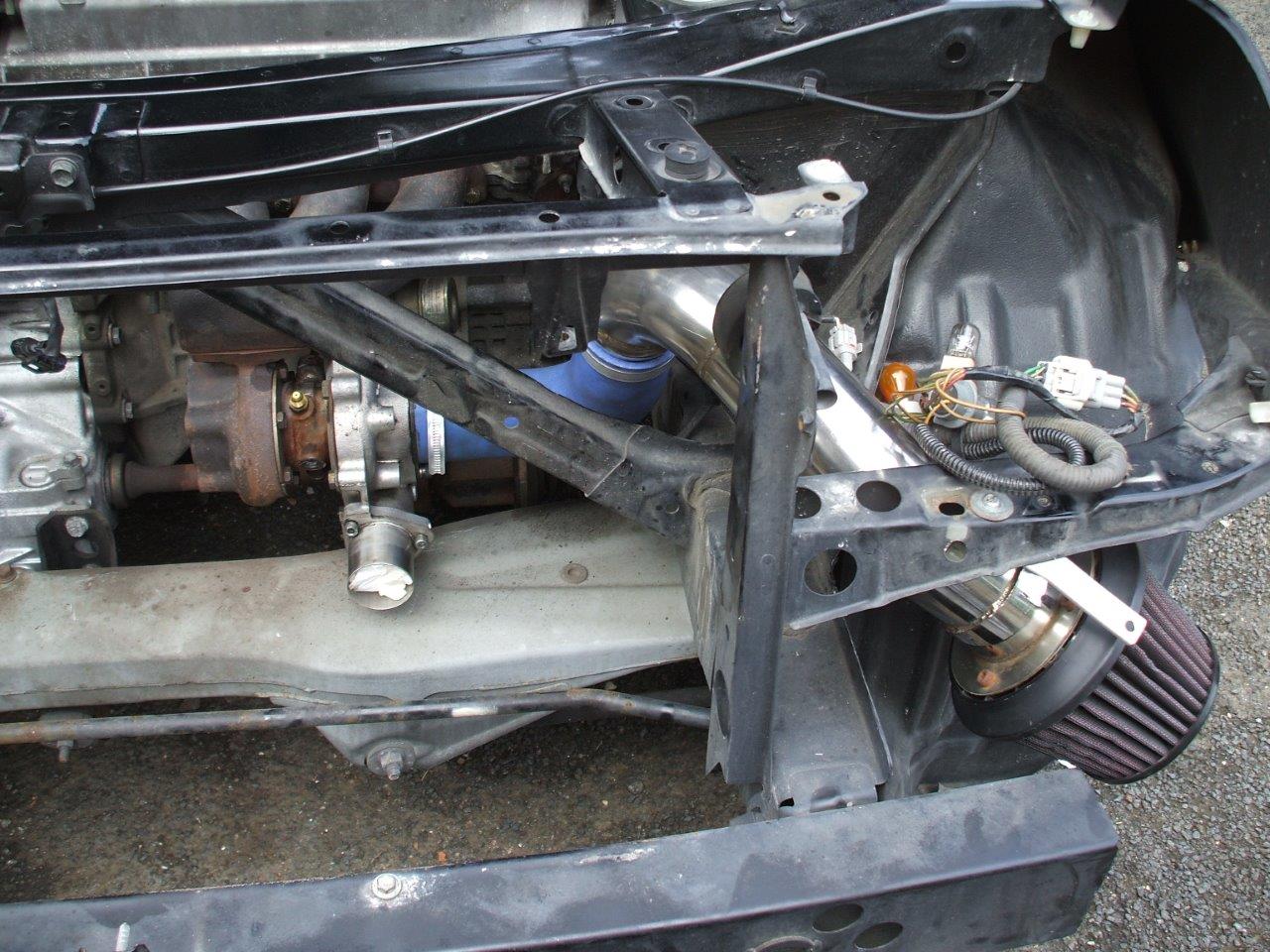

Once we eventually found the exhaust gasket after tearing the whole house apart (which was stuck to the side of the Clutch box in the house) Exhaust, Turbo bracing and Intercooler fitted (Intercooler still needs a bit of work):

I fitted new spark plugs and my bro soldered on the new Injectors. Fitted in the Emanage under the left bin and put all the gauge wires in through the right side and took a feed from the ignition switch on the stereo.

When then started her up just to reverse her up the ramps, first time start with no issues.

During the day we were halted by rain quite a few times so when it started up again we called it a night.

Sunday morning is when we found our problem... Removed the sump so that we could drill it:

We then went to test fit the sandwich plate for the oil return feed and realised that there was something missing... (quite an important bit at that!)

The core to extend the centre was not included (and we assume it's possibly still on the car) so there was no way we could screw the Oil Filter on to seal the Sandwich plate in place (UK car has an oil cooler so a longer core to start with, J-Spec doesn't have this so only enough thread for the Filter to fit

)... After a phone call to the very helpful Ste to see if he happened to have it lying around from the install we realised there was nothing we could do about that so we continued with the rest of the plumbing.

The next 'make shift' part was to drill the sump. As the biggest drill bit we had was a 16mm Wood drill

This was used at slow speed and surprisingly worked pretty well. I then filed the sides to the right size as the sump plug was 18/19mm then cleaned all the bits of metal out and fitted it along with some Loctite black sealant.

Sump plug fitted and putting the Loctite on to fit the sump back to the engine.

Sump fitted back in place and TRD Oil Filter installed temporarily.

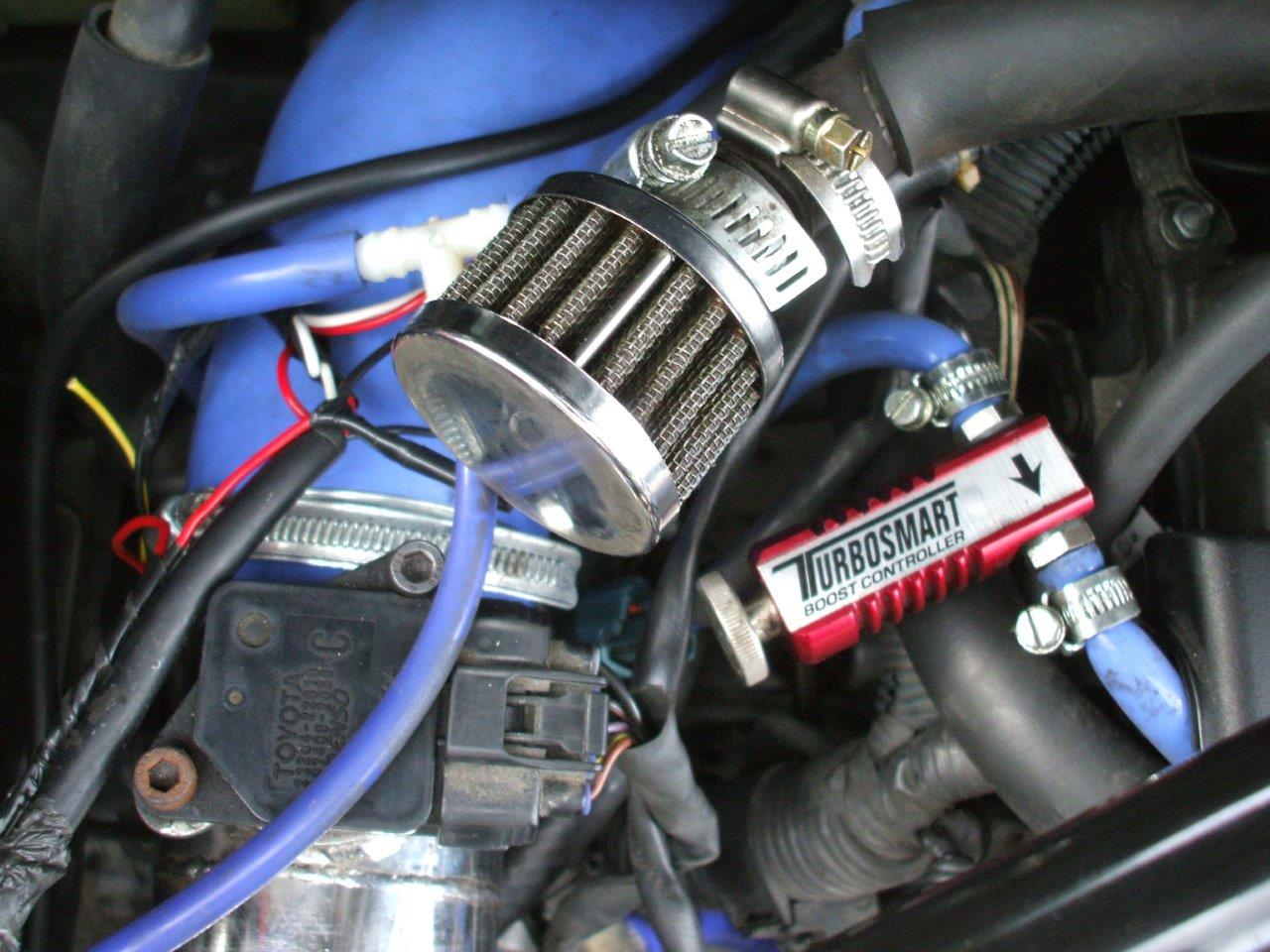

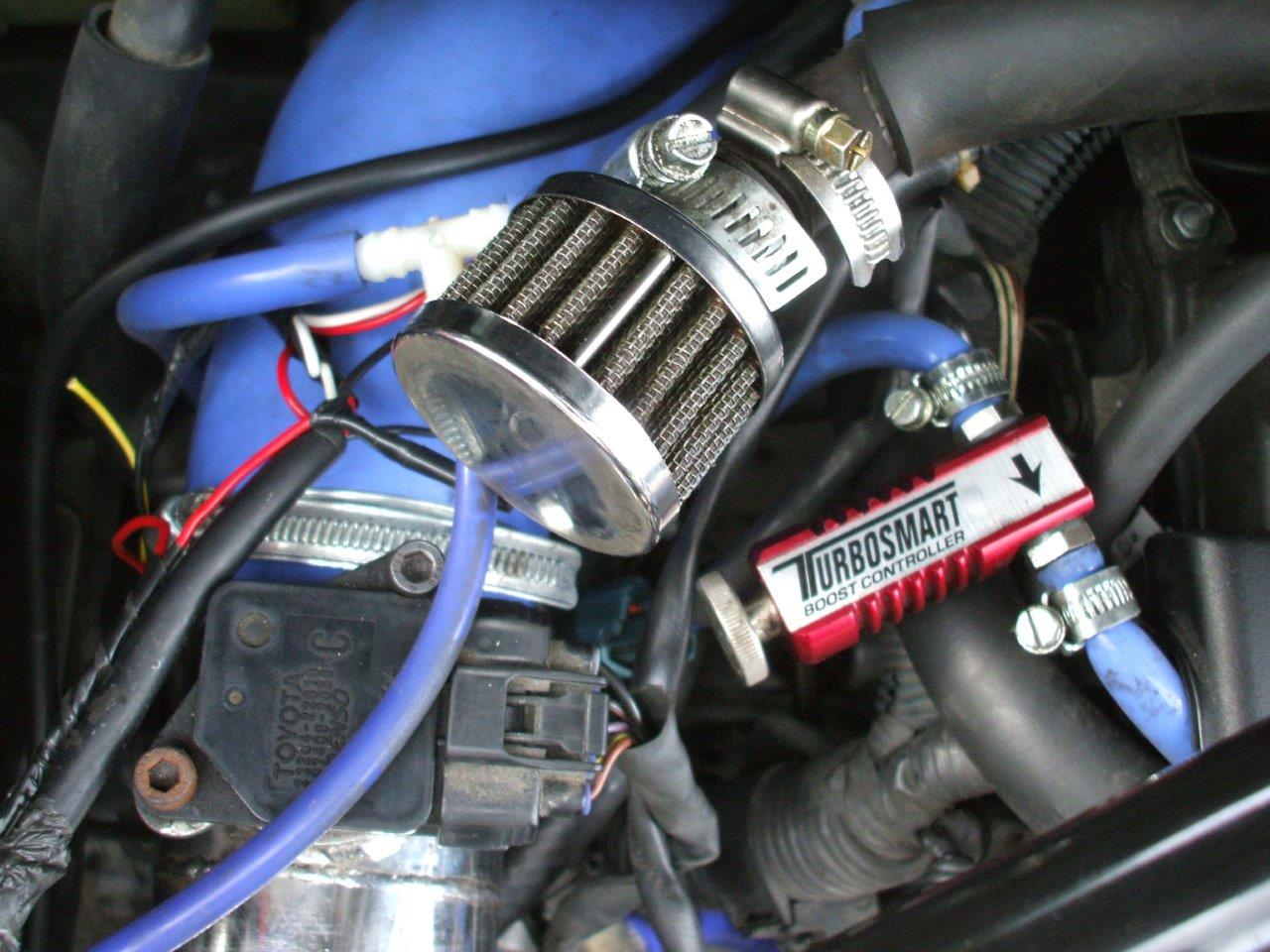

After another call to Ste we got the Boost Controller and Dump Valve (hopefully) fitted to the right places around the Throttle Body.

All finished, a nice full engine bay again.

Was a good weekend all in all where I've learned quite a bit and also got to get the most hands on work I've ever done (bro let me do most of it so I could learn!), the Chinese and the Curry helped out too. Got to speak to my 2nd ever ROC member so I am slowly meeting people after over a year... but sadly I missed the Softies run.

I'm quite gutted about the fact that I couldn't take the car away as there was no oil feed to the turbo and had to pay my bro to give me a lift back in the petrol guzzling Mk2 tubby but at least we will get a new core machined this week and I can get the train back up on Saturday to spend the 15 minutes needed to finish it off and can actually test it out more than just reversing 2 feet. Thanks to Ste for you availability to help.

Install

Install